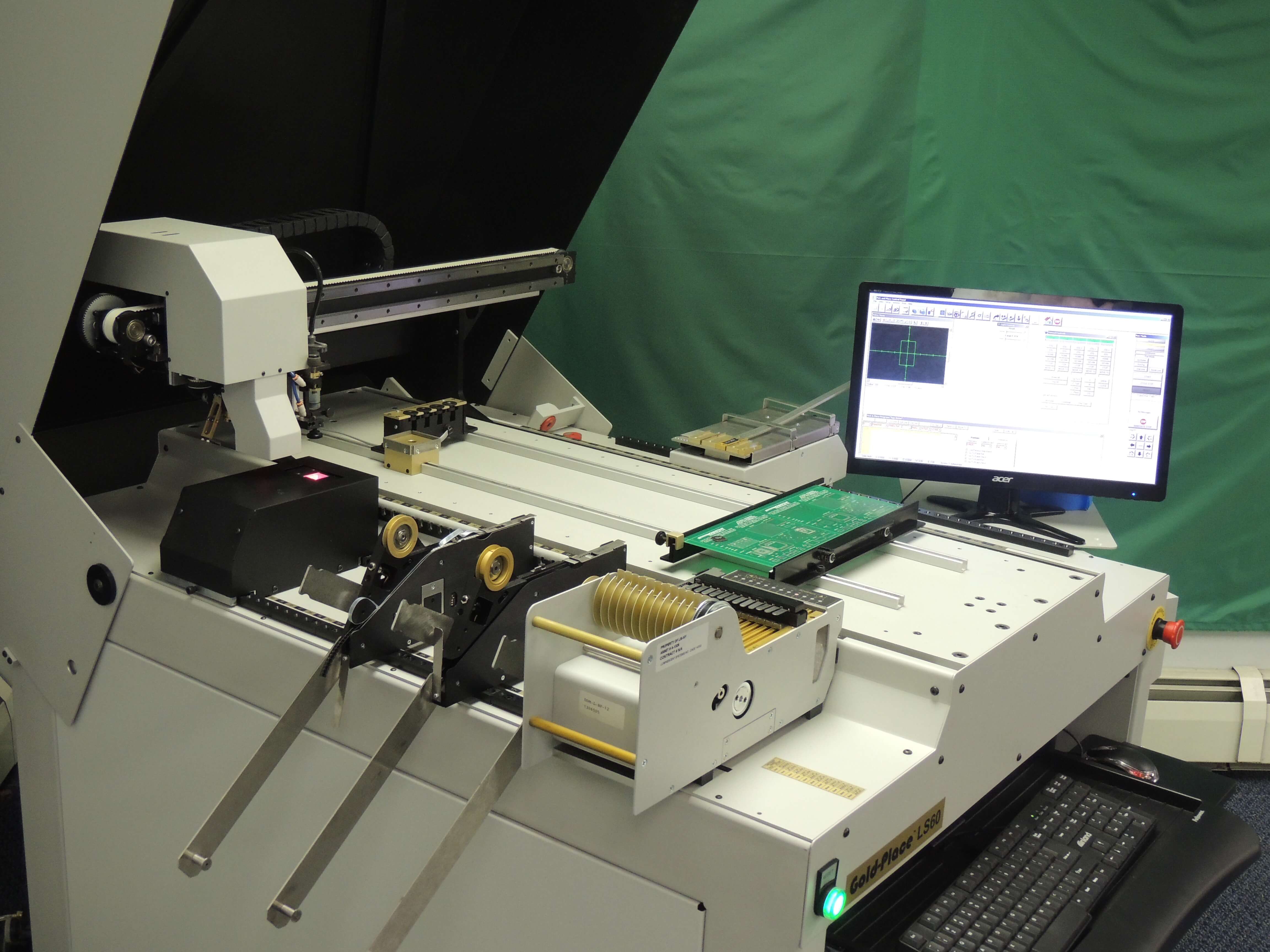

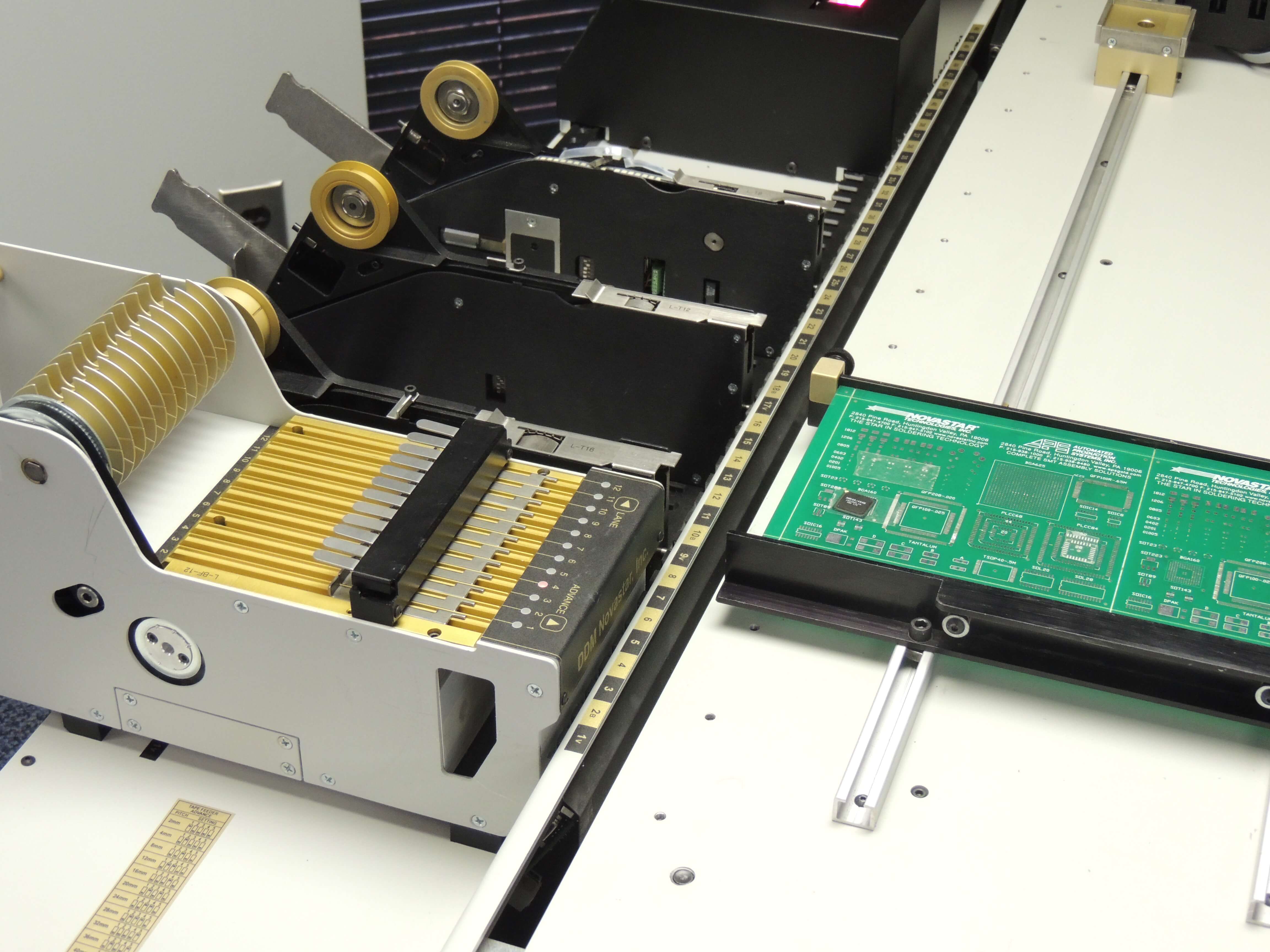

LS60V Pick and Place Machine with Vision

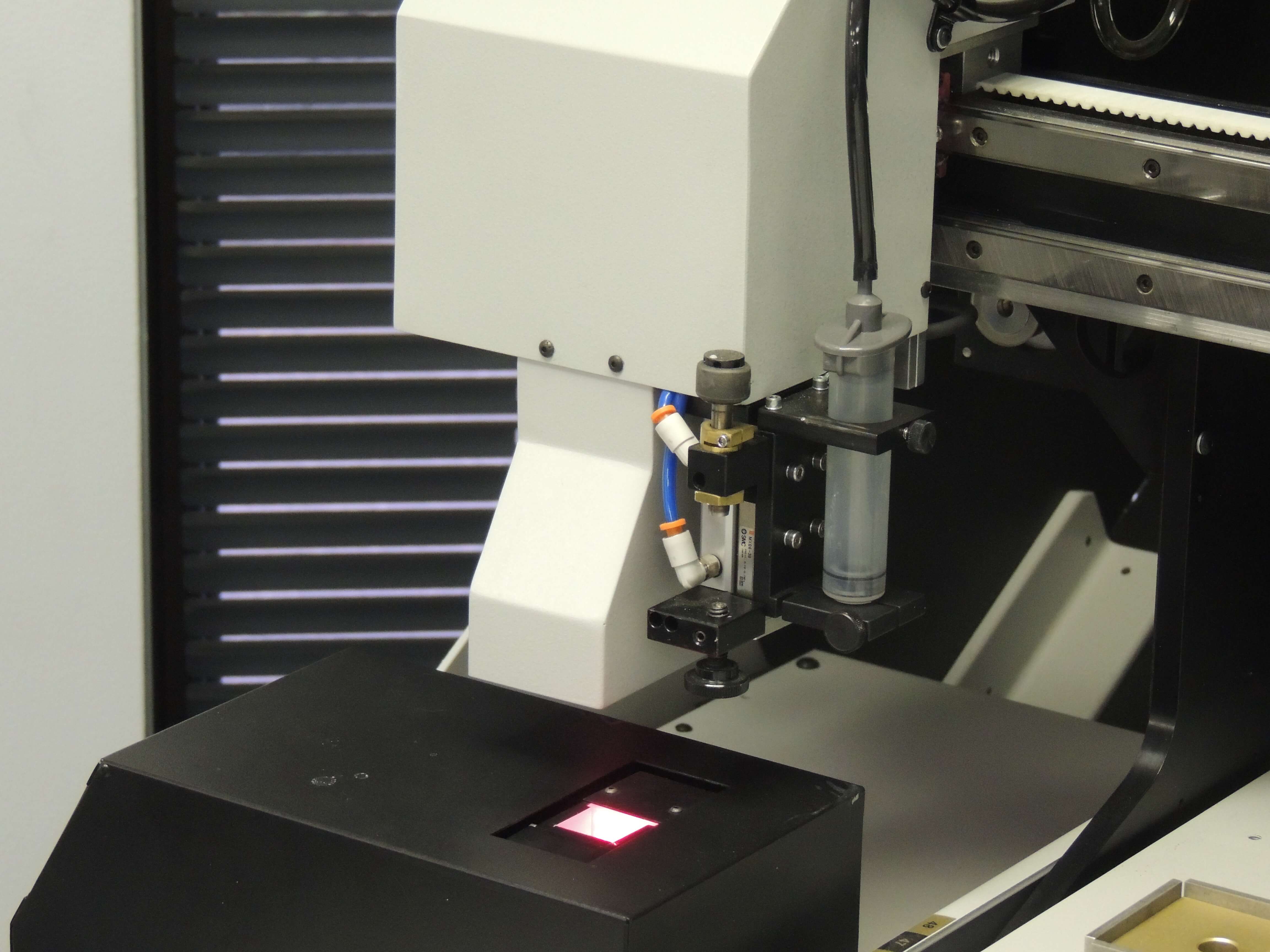

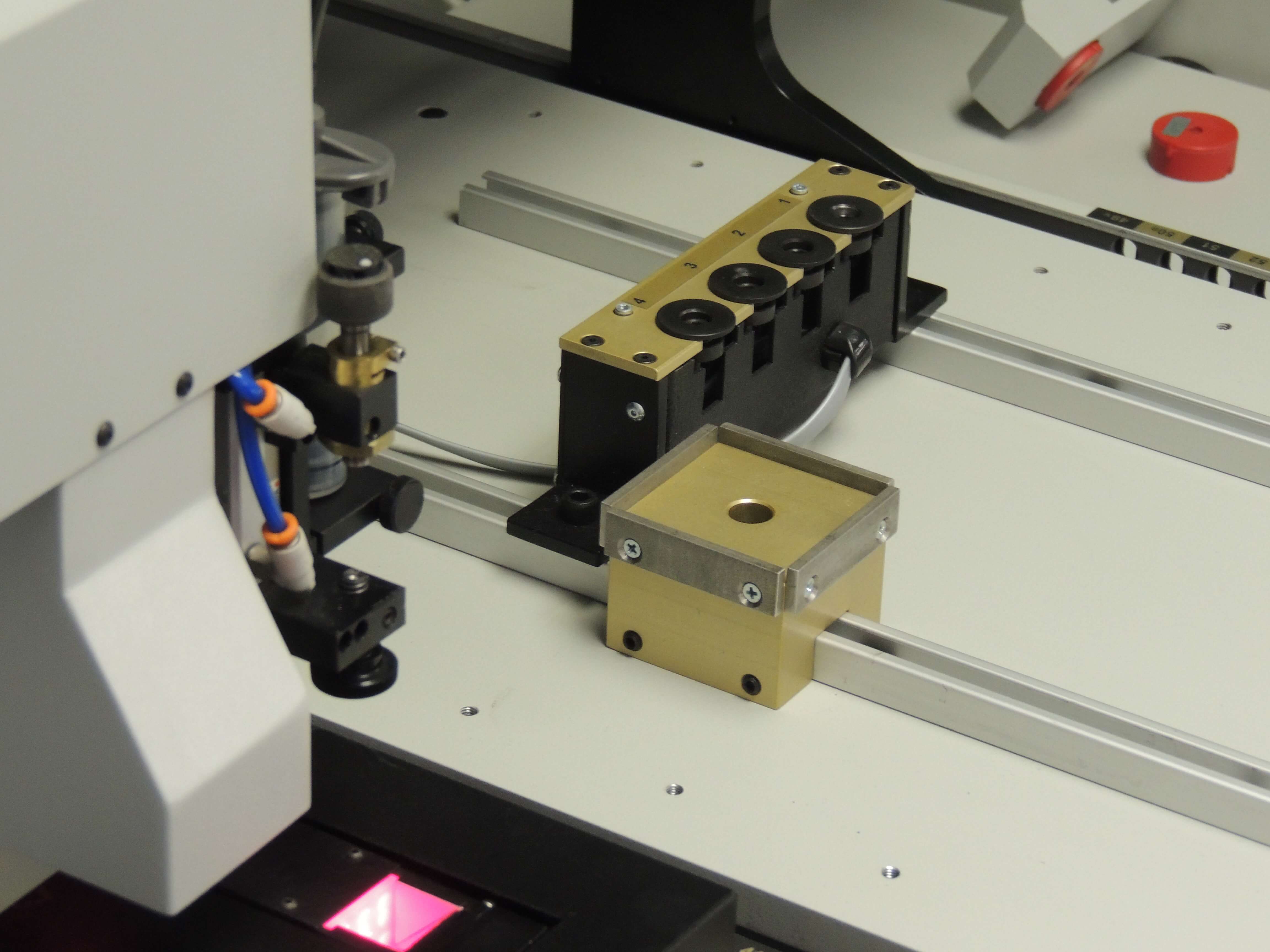

The LS60V is DDM Novastar’s most flexible pick and place system, engineered to combine advanced automation with ease of use. Featuring a spacious 13" x 32" (330mm x 813mm) work area and support for 88 standard single feeder positions—or up to 132 using bank feeders—it is built for quick setup, high reliability, and efficient, automatic production runs. With placement repeatability of ±0.02mm (20μm), the LS60V ensures consistent, high-precision results across demanding applications. The system handles components up to 2" x 2" x 5/8" (50mm x 50mm x 16mm) in size and comes standard with an automatic nozzle changer equipped with four precision nozzles from 0.025” to 0.109” ID. Specialty nozzles for extra-large, extra-small, and LED components are also available. For added convenience, the hinged machine covers lift up and out of the way, simplifying setup and changeover between board runs.

View a video "Overview on the L-Series Automated Pick and Place Machines"

Read the article "Selecting a Pick & Place Machine."

Placing LEDs? Also see:

LS60V-LED model for LED package placement applications or

request a quote for the

LS60V-LED, specifically

designed for LED specific applications.

Prototyping - Pilot Manufacturing - Low Volume Production

- The highest quality automatic pick and place machine with the most advanced technology at a cost effective solution

- Accuracy ± .001” (0.025mm)

- Placement rates up to 4800CPH

- The best GUI (graphical user interface) in its class using Windows-based software allows programming in minutes

- Up to 88 tape feeders, 132 - 8mm tape feeders with bank feeders

- Accurately places a wide range of components including 0201s, LED’s, BGAs, 15mil pitch QFPs, SMT Connectors and many others

- Servo driven, position feedback from a 2 micron linear scales coupled with a precision placement read

- Integrated on-the-fly component centering using Vision (Cognex®) or Mechanical fingers

- Accurately place, manage, and track components with SMTrue™ Smart Feeders

- Cut tape, loose, tube, or tray feeders

| Max board size | 13.5" x 32" (343mm x 813mm) |

| Smallest component capability | 0201 components |

| Largest component size | 2.00 |

| Placement accuracy | ± 0.001 |

| Max placement rate | 4800 cph |

| Typical verifiable placement rate | 2500-3600 cph |

| Fine pitch capability | To 15 mil pitch (0.381mm) |

| Max travel area | 22 |

| Overall dimensions | 40 |

| Max no. of feeders (8mm tape) | 88 |

| Max no. of feeders with L-GB-12 bank feeders | 132 |

| Tape feeders | 8, 12, 16, 24, 32, 44 mm (Electrical) |

| Vibratory Feeders | Loose, tube, stick (frequency & amplitude control) |

| Matrix Tray Feeders | With Board/Matrix tray holders |

| Centering | Centering Fingers |

| Vision system | Cognex® Vision |

| Dispenser Option | Up to 10,000 dots/hour |