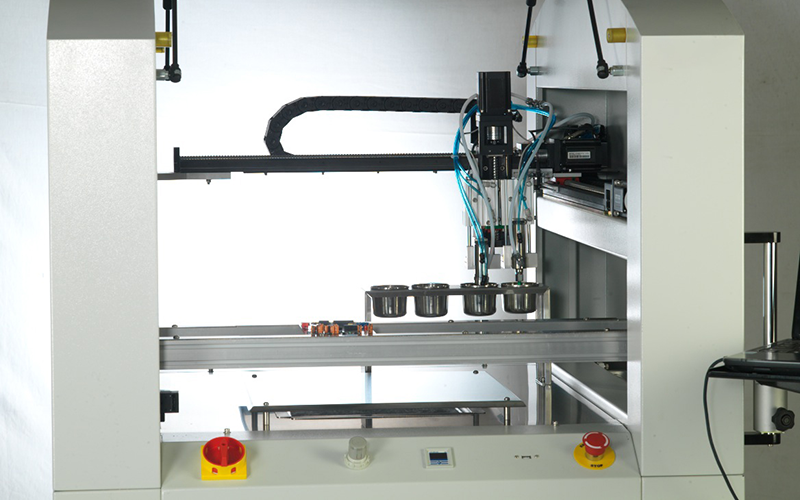

EasyCoat Conformal Coating System

Cost-effective solutions for the electronic industry

The EazyCoat system is ideal for selective conformal coating and dispensing applications which require a high level of accuracy and repeatability. It is an ideal solution for medium and low volume applications.

EazyCoat is equipped with a robust 3 Axis motion platform which can be mounted with any of the two valves. The valves can be used to manage spraying, dispensing or film coating.

EazyCoat works with a laptop computer. Programming is done easily by manual teaching or by using the JPEG image of the PCB. All the parameters such as valve and motion parameters can be altered easily. It can also be programmed for various shapes, patterns and areas.

Valve Option

- SV-500 Circular Spray pattern Valve

- DV-500 Needle Valve

- FV 500 Film Coating Valve

Coating Feed Option

- Cartridge Feed

- Pressure Vessel

Standard Feature

- Door interlock control

- Purge and Solvent Cups

- Light tower indicator

- Low exhaust interlock

- Control via Laptop Computer

Optional Feature

- Low level material sensor

- Internal UV Light

| Motion Control | |

| XYZ Axis drive | Stepper motors plus ball screw |

| XYZ Resolution | 25 Micron |

| Velocity | 350 mm/sec |

| Coating Area | |

| XYZ Travel | 430 mm x 430 mm x 50 mm (17" x 17" x 2.9") |

| Bottom side clearance | 100 mm (4") |

| Inline (Option) | |

| Conveyor Type | Pin or Chain |

| Minimum conveyor width | 50 mm (2") |

| Max. conveyor width | 430 mm (17") |

| Edge Clearance | 5 mm (0.2") |

| Transport Height | 940 mm - 965 mm (37" - 38") |

| Communication | SMEMA |

| Facilities Requirements | |

| Air Supply | 6 bar 85 PSI dry clean air |

| Exhaust | 250 m3, 127mm (5") dia |

| Power | 220 VAC, 50/60 Hz |

| Dimension | |

| Length | 1400 mm (55.1") |

| Width | 1000 mm (39") |

| Height | 1550 mm (61") |

| Weight | 275 Kgs (605 LB) |